Choosing the right 3D printer can be a daunting task, especially for someone who is new to 3D printing. With so many options available on the market, it can be challenging to determine which one is the best fit for your needs. This post will provide 3 key considerations to guide you to the right printer.

#1 Determine Your Primary Use

The first step in choosing the right 3D printer is to determine your needs.

Consider what you plan to use the printer for, the types of objects you want to print, the level of detail you need, and your budget. If you’re a hobbyist looking to print simple objects that don’t require intricate detail, then a budget-friendly printer may suffice. However, if you’re a professional designer/engineer or figurine enthusiast who needs high-resolution prints, you may need a more advanced printer.

Key takeaway: Understand your desired print volume and resolution.

#2 Choose Printer Type

The second step is to select the type of 3D printer that best suits your needs based on your primary use.

There are several types of 3D printers, including Fused Deposition Modeling (FDM), Stereolithography (SLA), Digital Light Processing (DLP), and Selective Laser Sintering (SLS). FDM printers are the most common and affordable, while SLA and DLP printers are better for high-resolution prints. And SLS printers are typically used in industrial applications for functional rapid prototypes and end-use parts.

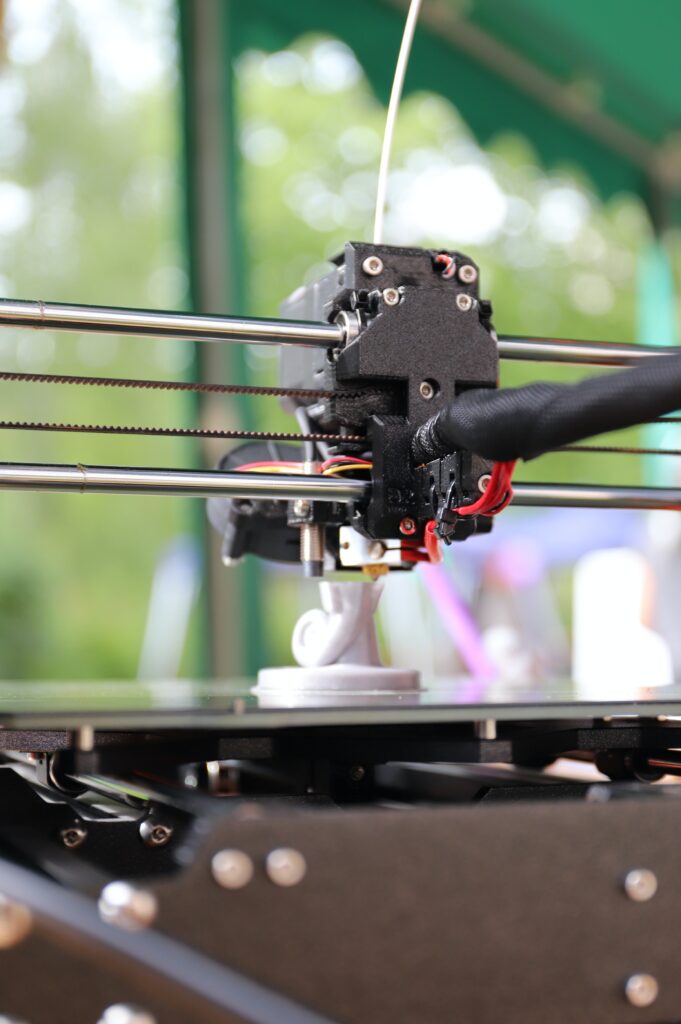

FDM, also known as Fused Filament Fabrication (FFF), is the most widely used type of 3D printing at the consumer level. The printing technology uses a thermoplastic filament, which is melted and extruded through a heated nozzle, layer by layer, to create a 3D object. FDM printing is widely used in various industries and applications, including product design, prototyping, architecture, engineering, and even personal hobbies and DIY projects.

Some use cases for FDM printing include creating functional prototypes, producing custom jigs and fixtures, creating architectural models, and even creating orthotics or prosthetics. FDM printing can also be used for creating intricate and artistic pieces.

However, there are certain scenarios where FDM printing may not be the most ideal option. For example, if you require extremely high-resolution or fine details for objects like miniatures/figurines or jewelry, then stereolithography (SLA) or digital light processing (DLP) 3D printing may be more suitable. SLA and DLP printing use a liquid resin that is cured using light, resulting in higher resolution and smoother surface finishes.

Another scenario where FDM printing may not be ideal is when producing parts that require very high strength and durability. These are best suited for aerospace components, automotive parts, and medical implants. SLS printing can produce parts with high dimensional accuracy, good surface finish, and excellent mechanical properties.

SLS printing can also produce complex geometries with internal channels, undercuts, and intricate shapes that are difficult or impossible to produce using FDM or SLA/DLP printing. This makes SLS printing ideal for producing complex mechanical parts, molds, and tools.

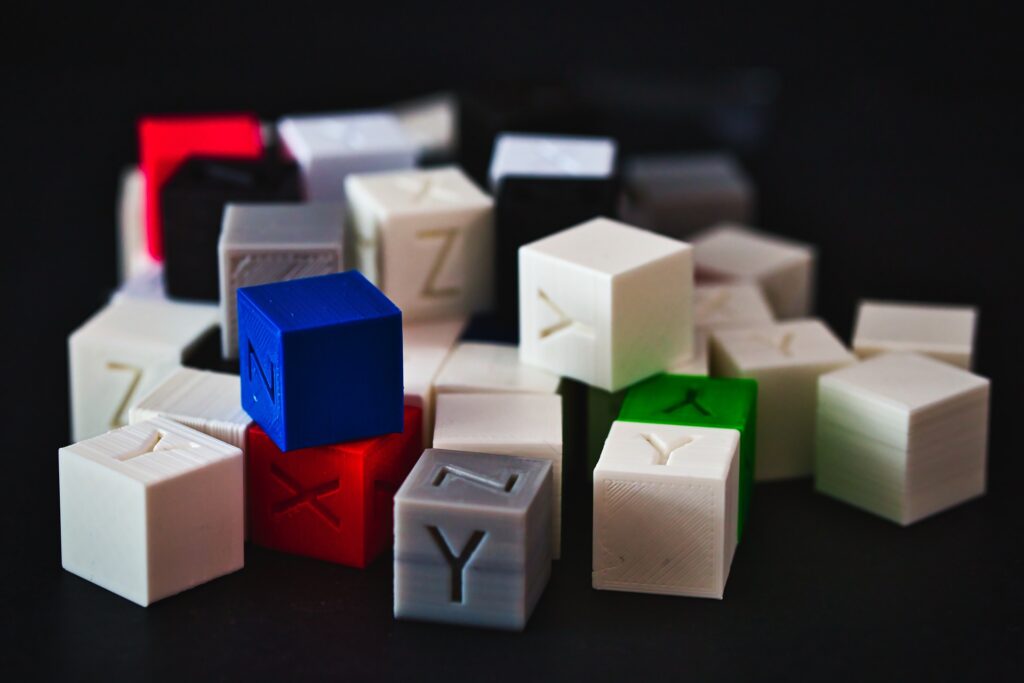

Key takeaway: FDM printers are the most versatile. SLA/DLP printers are best for small or high-detailed prints. SLS are for complex industrial applications.

#3 Evaluate Cost and Value

You most likely have an idea of how much money you are willing to spend on a 3D printer, but how much time are you willing to allocate to learn, maintain, and troubleshoot?

In general, FDM printers require less maintenance and troubleshooting than SLA/DLP printers.

FDM printers use a relatively simple extrusion mechanism and have fewer moving parts than SLA printers. This means they are generally less prone to mechanical failure and require less maintenance. FDM printers also have a simpler post-processing procedure, as the printed parts typically require only minor cleaning and sanding.

SLA printers, on the other hand, use a more complex mechanism involving a laser and a resin tank. The laser and optics components require regular cleaning and calibration, and the resin tank needs to be replaced periodically. Additionally, SLA printed parts require a more involved post-processing procedure that involves rinsing the parts in isopropyl alcohol and curing them with UV light.

Regardless of type, 3D printers can range in price from a few hundred dollars to several thousand dollars. Determine your budget and consider what features are most important to you.

Although budget-friendly FDM printers can be a good starting point for beginners, higher-cost printers typically offer improved build quality, faster print speeds, larger build volumes, higher print quality, and improved ease of use. They also often come with better customer support and technical resources, which can be important for those who rely on their printer for professional/commercial use or have little experience with 3D printing.

While budget-friendly 3D printers can deliver good print quality, they usually need more time and attention, as the 3D printing process isn’t always a simple plug-and-play experience, and some printers require more setup than others.

Key takeaway: FDM printing is the most cost-effective in terms of both money and time.

Final Thoughts

By following these steps, you can choose the right 3D printer for your needs and ensure you’re making an informed decision. With the right printer, you can take your DIY projects to the next level and unleash your creativity.